2026 Top Alloy Powder Grader How to Choose the Best?

Choosing the right Alloy Powder Grader can greatly impact production efficiency. As industry expert Dr. Emily Chen stated, "The right equipment makes all the difference." This statement emphasizes the importance of making informed choices when selecting an Alloy Powder Grader.

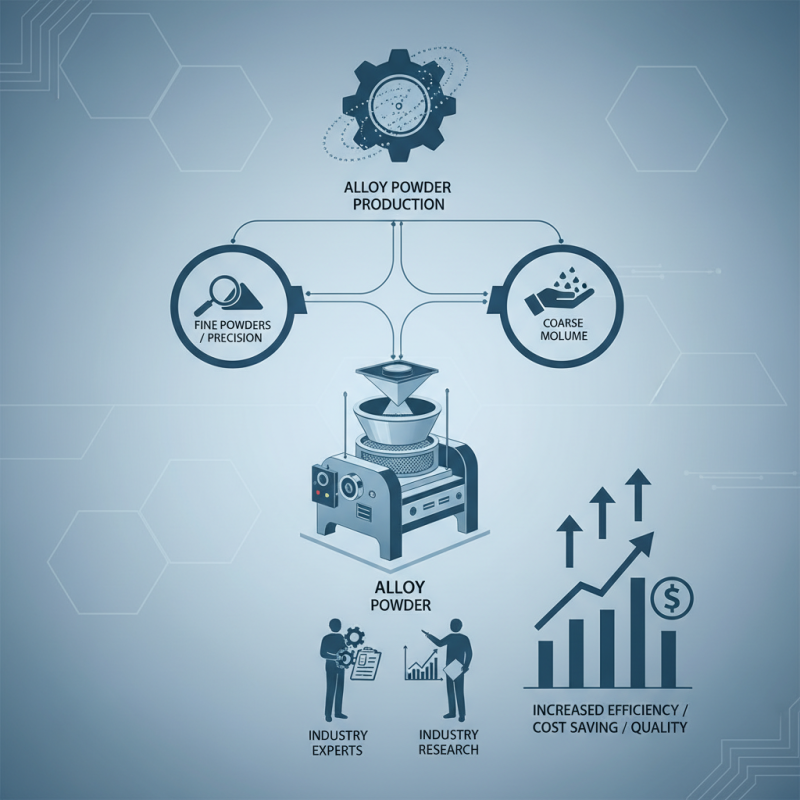

In the competitive market of alloy powder production, precision and quality are critical. Understanding the various types of graders available is essential. Many companies overlook this step. They rush into decisions, often leading to suboptimal outcomes. A thorough assessment of grading technology can save costs and enhance product quality.

It's vital to consider your specific needs. Not all graders suit every application. Some may focus on fine powders, while others handle coarser materials. The perfect Alloy Powder Grader for one company may not fit another. The choices can be overwhelming, but careful research can guide better decisions.

Understanding Alloy Powder Graders and Their Importance in Metallurgy

Alloy powder graders play a crucial role in metallurgy. They determine the quality and characteristics of metal powders used in various applications. Understanding these graders is essential for those in manufacturing and material science.

When selecting an alloy powder grader, precision is key. A good grader assesses particle size, shape, and distribution. These factors affect how the powder behaves during processing. For example, a finer powder may enhance flowability but could also lead to issues like agglomeration. It's a delicate balance that requires thoughtful consideration.

Not all graders provide the same level of detail. Some may overlook specific metrics that could be vital for your needs. It's common to focus solely on cost while ignoring performance metrics. Reflecting on past choices can help refine your selection process. Look for graders that offer comprehensive insights for better decision-making.

Key Factors to Consider When Selecting an Alloy Powder Grader

When selecting an alloy powder grader, several key factors come into play. The particle size distribution is crucial. According to industry reports, the optimal range for many applications lies between 10 µm and 45 µm. Selecting a grader that achieves this distribution can enhance both the quality and performance of the final product.

Another critical factor is the flowability of the powder. Poor flowability can lead to inconsistent results during production. Manufacturers should consider the angle of repose, which ideally should be under 30 degrees for efficient processing. Additionally, the moisture content should be kept below 0.5% to prevent clumping.

One often overlooked aspect is the maintenance and calibration needs of the grader. Regular adjustments ensure accurate measurements. It's easy to forget this step amid production pressures. This oversight might lead to significant variations in grading quality. Regular checks can save costs and improve yield, reaffirming the value of investing time into this process.

Different Types of Alloy Powder Graders and Their Applications

When selecting an alloy powder grader, understanding its types and applications is crucial. Alloy powder graders vary in design and functionality. Some focus on particle size distribution, while others emphasize material efficiency. A study from the International Journal of Powder Metallurgy indicates that precise grading affects material properties significantly. For example, finer powders enhance sintering processes in additive manufacturing.

Applications for these graders span multiple industries. In aerospace, specific particle sizes improve the strength-to-weight ratio of components. In electronics, the right grading can impact conductivity and durability. However, not all graders perform equally under different conditions. A report from the Metallurgical Society shows that inappropriate grading can lead to material waste and inconsistent product quality.

Choosing the right alloy powder grader requires careful consideration. Users must evaluate their specific needs and the grader's capabilities. Sadly, some overlook this step. Compromising on a grader can lead to costly mistakes down the production line. Ultimately, being informed can guide better decisions and improve manufacturing processes.

Evaluating Performance Metrics of Alloy Powder Graders

Choosing the best alloy powder grader requires careful evaluation of key performance metrics. Start with precision. Accuracy in measuring particle size is critical. An accurate grader ensures the material meets strict specifications. Investigate the range of sizes it can analyze. This can affect the final application of the alloy.

Consider the speed of the grading process. A faster system might seem better, but it shouldn't sacrifice accuracy. Some graders struggle at higher speeds, leading to errors. Evaluate whether a compromise might be necessary for your specific needs.

Tips: Always calibrate your device regularly. Regular maintenance enhances performance. Create a checklist to ensure you don’t overlook anything. Testing different techniques can also reveal unexpected results. Sometimes, a more precise manual method can outperform a faster machine. Reflect on your findings to make informed decisions.

Future Trends and Innovations in Alloy Powder Grading Technology

The alloy powder grading technology is evolving rapidly. Advances in particle size measurement play a crucial role in this field. Recent studies report that precision in grading can improve production efficiency by 30%. New methods include laser diffraction and dynamic image analysis. These innovations promise better accuracy and reliability in results.

The industry is moving towards automation. Automated grading systems can provide real-time data analysis. This shift not only enhances productivity but also minimizes human error. Reports indicate that companies adopting automated systems have seen a 20% rise in output. However, integration can be challenging. Many companies face difficulties in upgrading existing equipment. This requires careful planning and resource allocation.

Tips: When selecting grading technology, consider accuracy and speed. Look for systems that offer real-time monitoring. Also, assess your budget and training needs. It's essential to strike a balance between efficiency and cost. Engaging with industry experts can provide valuable insights.

2026 Top Alloy Powder Grader: Trends in Grading Technology

This bar chart represents the projected advancements in alloy powder grading technology by 2026, focusing on key factors such as accuracy, speed, and efficiency.