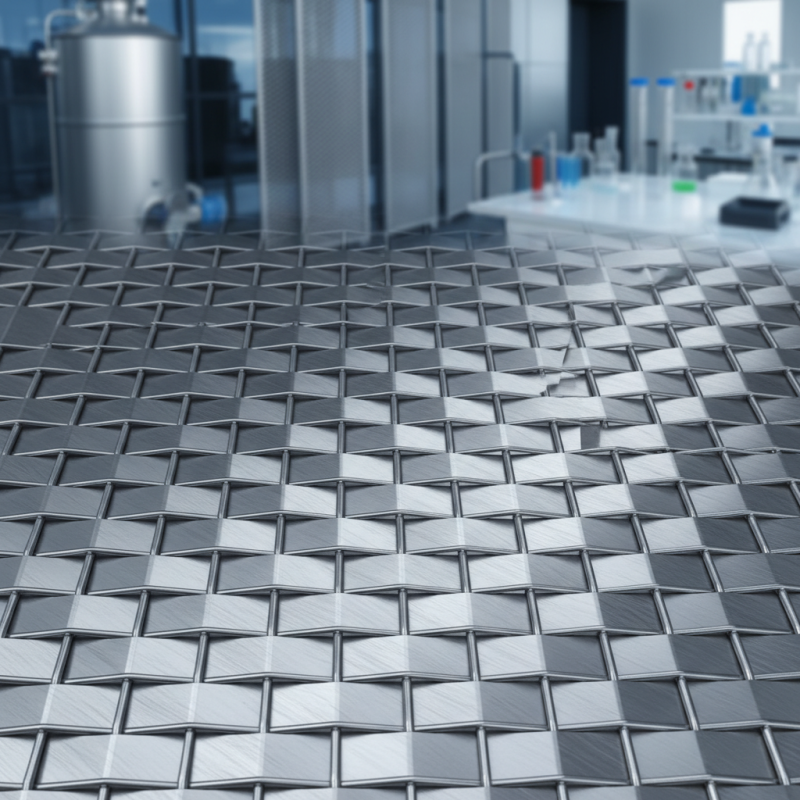

Why Choose Stainless Steel Woven Wire Mesh for Your Projects?

stainless steel woven wire mesh is a versatile material used in numerous industries. Its durability and resistance to corrosion make it an ideal choice. According to a recent industry report, the demand for stainless steel mesh products is projected to grow at a rate of 5.4% annually through 2025. This growth is driven by the increasing need for filtration and screening solutions.

This type of mesh offers numerous benefits. It withstands harsh environments and maintains structural integrity. Moreover, its aesthetic appeal adds value to various projects. However, some users may overlook its advantages due to cost concerns. Balancing quality and expense can be tricky, yet stainless steel woven wire mesh often proves more economical in the long run.

Many applications benefit from this material. From industrial filtration to architectural designs, its versatility is unparalleled. Yet, the selection process can feel overwhelming. It's crucial to reflect on project needs and mesh specifications. Engaging with experts can clarify the best options. With thoughtful consideration, stainless steel woven wire mesh can elevate your project outcomes significantly.

Benefits of Stainless Steel Woven Wire Mesh in Industrial Applications

Stainless steel woven wire mesh is a top choice for many industrial projects. Its durability is unmatched, making it suitable for various applications. This mesh can withstand harsh environments without rusting or weakening. Many industries benefit from its strength and resilience.

In food processing, stainless steel mesh ensures that hygiene standards are met. It helps prevent contamination while allowing air and liquids to pass through. In filtration applications, this type of mesh is efficient and long-lasting. However, costs can be high during installation. Organizations may need to assess their budget carefully.

Another advantage of stainless steel mesh is its versatility. It can be used in construction, mining, and agriculture. Each industry requires specific mesh sizes and styles. Sometimes, finding the right mesh can be challenging, leading to trial and error. Selecting the wrong type may affect overall efficiency. Ensuring you have the best fit for your needs is crucial.

Why Choose Stainless Steel Woven Wire Mesh for Your Projects? - Benefits of Stainless Steel Woven Wire Mesh in Industrial Applications

| Application | Benefits | Material Specification | Common Uses |

|---|---|---|---|

| Filtration | Durability and resistance to corrosion | 304, 316 Stainless Steel | Oil and gas, water treatment |

| Architecture | Aesthetic appeal with strength | AISI 304 | Facades, decorative elements |

| Food Processing | Non-reactive and hygienic | 316 Stainless Steel | Screens, strainers |

| Mining and Quarrying | High tensile strength | AISI 304/316 | Vibrating screens, sifting |

| Pharmaceuticals | Meets stringent hygiene standards | AISI 316 | Filtration, containment |

Durability and Corrosion Resistance of Stainless Steel Materials

When considering materials for industrial projects, stainless steel woven wire mesh stands out. Its durability and corrosion resistance are significant advantages. According to industry reports, stainless steel can resist oxidation and corrosion for decades. This long lifespan makes it ideal for harsh environments.

Corrosion resistance is crucial in many applications. For instance, areas with high moisture or exposure to chemicals need reliable materials. Stainless steel retains its integrity in these settings. A study showed that stainless steel maintains strength and performance even under extreme conditions. This reliability can reduce maintenance costs over time.

Tips: Always consider the specific environment where the mesh will be used. Understand the type of corrosive elements present. Regular inspections can help catch issues before they escalate. Explore different grades of stainless steel, as each offers unique benefits. Balancing cost and performance is vital; sometimes, a less expensive option might seem tempting, but it may not provide the long-term benefits of higher-quality materials.

Market Trends: Demand for Stainless Steel Woven Wire Mesh in Various Industries

The demand for stainless steel woven wire mesh is rising across multiple industries. Its versatility makes it a popular choice. Construction, manufacturing, and food processing sectors are increasingly adopting this material. Companies appreciate its corrosion resistance and strength. This mesh offers excellent filtration properties, enhancing production efficiency.

In the construction industry, stainless steel mesh is often used for safety barriers and architectural elements. It provides durability while maintaining aesthetic appeal. In the food industry, hygiene is crucial. Using stainless steel mesh meets health standards effectively. However, not all wires are manufactured the same. Quality can vary, impacting performance and safety.

While there is a clear trend towards stainless steel woven wire mesh, some challenges remain. Not every project can accommodate it due to cost constraints. It's essential to analyze individual needs carefully. Understanding the specific requirements and limits of a project ensures better outcomes.

Market Trends: Demand for Stainless Steel Woven Wire Mesh in Various Industries

Cost-Effectiveness: Comparing Stainless Steel with Other Mesh Materials

Stainless steel woven wire mesh is gaining popularity for various projects, and its cost-effectiveness stands out. Compared to other mesh materials, stainless steel offers superior durability and strength. While initial costs may seem higher, consider the long-term benefits. Stainless steel resists corrosion and wear better than alternatives. This means less frequent replacements and lower maintenance costs.

Many professionals overlook the hidden expenses of cheaper materials. For instance, aluminum or plastic meshes may degrade quickly in harsh environments. They can develop tears, leading to safety concerns and more frequent replacements. It’s a frustrating cycle. Investing in stainless steel upfront can mitigate these problems.

Choosing the right material shouldn't be taken lightly. Think about the environment where the mesh will be used. Will it face extreme temperatures or moisture? These factors matter and can affect your budget. Options exist, yet the upfront costs of stainless steel sometimes leave people hesitant. However, it’s often the wiser choice in the long run.

Key Specifications and Standards for Quality Stainless Steel Wire Mesh

Stainless steel woven wire mesh is a popular choice for various projects due to its durability and resistance to corrosion. When selecting this material, understanding key specifications and standards is crucial. The mesh's wire diameter and opening size significantly influence its performance. A thicker wire offers greater strength but may limit airflow. Conversely, a finer mesh enhances filtration but may struggle with heavier loads.

Quality standards, such as ASTM and ISO, ensure that the mesh meets specific criteria. These standards help establish parameters for tensile strength and corrosion resistance. However, not all manufacturers adhere strictly to these benchmarks. This inconsistency can lead to varying product quality in the market. It's essential to verify product certifications and ask suppliers about their compliance.

In practice, attention to detail matters. The choice of stainless steel grade also impacts longevity. For example, 304 stainless steel is common but may not perform as well in harsher environments compared to 316 stainless steel. Projects often reveal unforeseen challenges. Regular testing and maintenance are critical, as overlooking minor details can lead to significant issues later on.