Why Choose Stainless Steel Wire Mesh for Your Projects?

In recent years, the demand for stainless steel wire mesh has surged across various industries. Reports indicate a significant growth rate, with the global market expected to reach $3 billion by 2025. This growth is fueled by the material's durability and resistance to corrosion. Richard Lawson, a noted expert in material engineering, remarked, "Stainless steel wire mesh combines strength with versatility, making it a preferred choice in many applications."

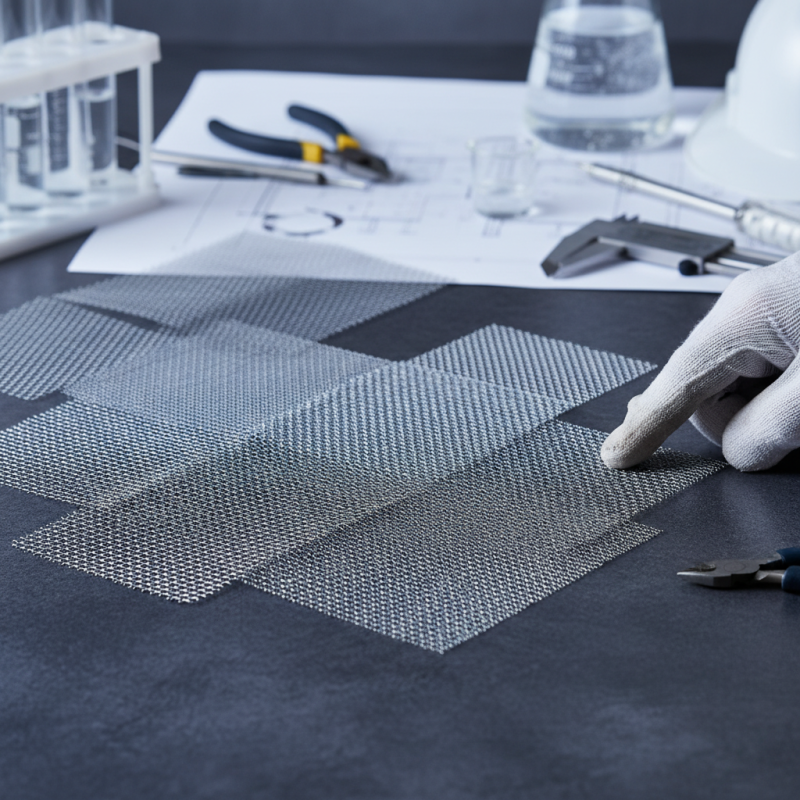

stainless steel wire mesh is widely used in construction, filtration, and automotive sectors. Its unique properties allow it to withstand extreme conditions while maintaining structural integrity. Many professionals appreciate its adaptability, yet some still overlook the long-term value it provides. This oversight can lead to higher replacement costs later.

Despite its many advantages, choosing stainless steel wire mesh is not without challenges. Selection criteria can be complex and often require expert guidance. Understanding specific project needs is crucial. In a world where seemingly minor details can impact overall success, the right material choice becomes paramount.

Benefits of Using Stainless Steel Wire Mesh in Various Applications

Stainless steel wire mesh is a versatile material used in many industries. Its durability makes it ideal for various applications. For instance, in construction, it enhances strength and stability. Architects often choose it for facades and safety barriers.

In the food industry, stainless steel wire mesh is crucial for filtration and separation. It can withstand high temperatures and corrosive substances. This assurance of hygiene is vital in food processing. However, choosing the right mesh size is essential for optimal filtration.

Environmental factors also play a role. In outdoor applications, stainless steel resists rust and degradation. Yet, exposure to harsh chemicals can still lead to wear over time. Regular maintenance is important to ensure longevity. Overall, while stainless steel wire mesh has many advantages, caution is needed to maximize its benefits.

Durability and Corrosion Resistance of Stainless Steel Wire Mesh

Stainless steel wire mesh stands out due to its exceptional durability and corrosion resistance. In environments where moisture and chemicals are prevalent, standard materials may quickly degrade. Stainless steel, however, is known for its ability to withstand harsh conditions. A study by the International Stainless Steel Forum indicates that stainless steel can last up to 100 years in certain applications. This longevity not only reduces replacement costs but also minimizes maintenance efforts.

Corrosion resistance is a key feature of stainless steel wire mesh. The alloying elements in stainless steel create a protective layer that prevents rust. According to the American Society for Testing and Materials, stainless steel types such as 304 and 316 are highly resistant to pitting and crevice corrosion. This means they can maintain their integrity even in saline or acidic environments. Many projects overlook the importance of selecting the right material. The wrong choice can lead to failures and increased costs over time.

Yet, it's essential to note that not all stainless steel is created equal. Factors like weld quality and the specific environment can affect performance. Sometimes, users may prefer a lower grade to save initial costs. However, in the long run, this can be a costly mistake. Careful consideration of material choice is necessary to ensure project success.

Versatility of Stainless Steel Wire Mesh in Different Industries

Stainless steel wire mesh is a popular choice in various industries due to its unmatched versatility. In construction, it serves as reinforcement to improve structural integrity. The report from the Global Stainless Steel Market estimates that the demand for stainless steel wire products will grow by 7% annually. This growth is fueled by increased constructions and infrastructure projects worldwide.

In the food industry, stainless steel wire mesh is used for filtration and sieving. Its corrosion resistance and durability make it ideal for processing food products. According to industry analysts, the food safety market is expected to reach $20 billion by 2025. Businesses benefit from using stainless steel mesh as it meets hygiene standards while enhancing productivity.

Tips: When selecting stainless steel wire mesh, consider the grade based on your specific application. Not all stainless steel is created equal. Some projects may require higher grades for better longevity. Additionally, ensure mesh size matches your requirements to avoid complications later.

Reflecting on its uses, it is crucial to analyze the right wire specifications for unique projects. Engineers sometimes overlook this, leading to unexpected failures. The adaptability of stainless steel wire mesh, while advantageous, also demands careful assessment to truly harness its benefits in diverse applications.

Comparative Analysis of Stainless Steel and Other Wire Mesh Materials

When comparing stainless steel wire mesh to other materials, there are several key factors to consider. Stainless steel offers excellent corrosion resistance. In harsh environments, like coastal areas, this advantage is essential. Other materials, like aluminum, can corrode quickly in similar conditions. For projects that demand durability, stainless steel is often the superior choice.

Another aspect is strength. Stainless steel mesh provides high tensile strength. This makes it suitable for applications under heavy loads. In contrast, plastic or fiberglass mesh lacks this robustness. It may warp or sag over time. The longevity of stainless steel renders it a cost-effective option, despite potentially higher initial costs.

However, weight can be a drawback. Stainless steel is heavier than other materials. It may complicate installation processes. We must acknowledge this issue and plan accordingly. The aesthetic appeal of stainless steel is another factor. Its sleek appearance fits well in modern designs, unlike some other options. Nonetheless, the choice depends on the specific project needs. Balancing these elements requires careful consideration.

Maintenance and Care Tips for Stainless Steel Wire Mesh Products

Stainless steel wire mesh offers durability and versatility, but it also requires proper care. Regular maintenance helps prevent corrosion and maintains its aesthetic appeal. Cleaning the mesh should be a routine task. Use mild soap and water, avoiding harsh chemicals. These chemicals can damage the finish and compromise the material.

When storing stainless steel wire mesh products, keep them in a dry place. Exposure to moisture may lead to rust formation, even on stainless steel. Inspect the mesh regularly for any signs of wear or damage. Small issues can escalate into major problems if neglected. Sealing or refinishing may be needed occasionally to protect the mesh.

Occasional deep cleaning is beneficial. A simple scrub with a non-abrasive tool can remove stubborn residues. However, overzealous scrubbing might scratch the surface, leading to more maintenance. It's important to find the right balance in care. Each wire mesh type may have different needs, so developing a tailored maintenance routine is essential for longevity.