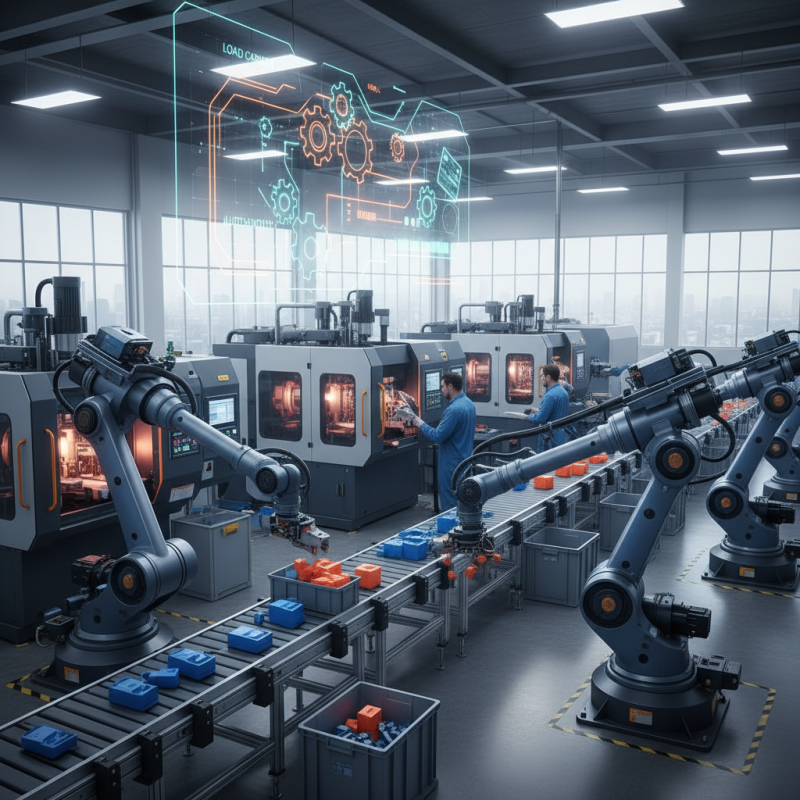

How to Choose the Right Injection Machine Robot for Your Needs?

Choosing the right Injection Machine Robot can be challenging. Renowned expert Dr. Emily Carter states, "Selecting the appropriate robot involves understanding your production needs." This advice resonates deeply in today’s manufacturing landscape.

Injection Machine Robots enhance precision and efficiency. However, the complexities of your operations influence which model suits you best. Factors such as load capacity, speed, and automation level must be considered. For instance, a high-speed production line may require a different solution than a low-volume operation.

It’s essential to weigh your options carefully. Not all machines are created equal, and misalignment can lead to inefficiencies. Investing in a robot without thorough research can result in unexpected costs. Take time to analyze your specific requirements. A thoughtful approach ensures that you choose an Injection Machine Robot that truly meets your needs.

Understanding the Different Types of Injection Machine Robots

Choosing the right injection machine robot requires understanding the various types available. There are several categories of injection robots, including Cartesian, SCARA, and six-axis articulated robots. Each type has unique features and benefits suitable for different applications. For instance, Cartesian robots are often used for linear movements. They excel in precision and are ideal for repetitive tasks.

SCARA robots have a distinct advantage due to their flexibility. They can easily handle complex assembly tasks. However, they may lack some precision when compared to Cartesian models. Six-axis articulated robots are versatile and can operate in tight spaces. Their design allows for a wide range of movement, making them suitable for more intricate operations. Yet, they can also be more challenging to program.

When deciding which robot to use, consider the specific needs of your operation. Assess the materials being processed and the complexity of the tasks. It's easy to overlook the potential limitations of each option. Perhaps a robot seems perfect at first glance. Still, it may not be the best fit in practice. Aim for a solution that balances flexibility and precision for your unique needs.

Injection Machine Robot Types Comparison

This chart compares the payload capacity of different types of injection machine robots. Understanding these distinctions can help you choose the right robot for your specific manufacturing needs.

Key Features to Consider When Selecting an Injection Machine Robot

When selecting an injection machine robot, key features make all the difference. You should consider payload capacity. This defines how much weight the robot can handle. If you have heavy molds, choose a robot with a higher capacity.

Speed is another important factor. Some tasks require quick cycles, so look for robots with a fast response time. However, speed can sometimes affect precision. Balancing these aspects is crucial. Think about the application you need.

Lastly, flexibility is vital. Can the robot adapt to different molds? Robots with interchangeable end effectors offer more versatility. Keep in mind that advanced features can come with a learning curve. There’s always a need to evaluate how technology fits your production line. Finding the right balance of features requires careful thought.

Assessing Your Specific Production Needs and Application Requirements

When selecting an injection machine robot, understanding your specific production needs is crucial. Assessing your application requirements helps to narrow down options. Consider the types of materials you will use. Different materials may require different robotic configurations. Additionally, think about the production volume. Higher volumes might demand faster and more efficient machines.

Another aspect to assess is the layout of your production line. The available space can limit your choices. A large robot may not fit in a smaller area. Conversely, a compact solution might not support high-output needs. Evaluate whether versatility is essential. For example, a robot that can handle various molds may be more beneficial than one with a singular purpose.

It's worth noting that not all robots perform equally. Some may excel in speed but lack precision. Others might offer precision but slow down production times. Reflect on your priorities and the potential trade-offs. Sometimes, the best choice may involve compromises. Understanding these dynamics will lead to more informed decisions. Your production environment is unique; take the time to analyze all factors for the best outcome.

Evaluating Budget Constraints and Cost-Effectiveness of Robots

When selecting an injection machine robot, budget constraints are crucial. The initial purchase price can greatly impact overall costs. However, it is essential to evaluate the robot's long-term value. A cheaper model may lead to higher operational costs over time. Maintenance and energy consumption can add significant expenses.

Consider the specific needs of your production line. A robot with advanced features might seem costly at first, but it could enhance efficiency. Inadequate equipment might create bottlenecks. This could affect production targets and lead to lost revenue. You must balance initial costs with potential gains.

Cost-effectiveness is not just about the initial investment. Think about how often repairs occur. Frequent breakdowns waste time and resources. Choosing the right robot means considering every aspect. Reflecting on what your team truly needs is critical. Sometimes, a less flashy option could better serve your goals.

Comparing Leading Brands and Models in the Market

When selecting an injection machine robot, you will find many brands and models available. Each option comes with unique features and capabilities. It could be overwhelming to decide which is right for your production line. Focus on your specific needs, such as the volume of production, part size, and automation level. For example, some robots excel in high-speed tasks, while others are designed for precision in smaller applications.

Take the time to read reviews and compare specifications. Brands may vary in reliability and support. Look for user experiences that highlight both strong points and weaknesses of each model. A common issue is the calibration and maintenance. Some machines require frequent adjustments, which can slow down the process. Analyze whether you have the expertise available to handle these challenges.

Cost is an important factor. Setting a budget influences your choices. High-priced models may offer advanced features, but not always necessary for all applications. Weigh the benefits against your operational needs. Researching warranty terms and support availability can also help inform your decision. Sometimes the best choice might not be the most expensive one. Making a thoughtful comparison will lead you closer to the right machine for your needs.