What is a Motorized Valve and How Does It Work?

A Motorized Valve is a key component in many systems. It plays a crucial role in controlling the flow of fluids or gases. These valves can operate automatically, responding to signals from a control system. They are often used in heating, cooling, and water management.

Motorized Valves come in various designs. Some are simple, while others are complex and require careful installation. Understanding how they work can help in choosing the right type for a specific application. Proper installation can enhance performance. However, improper installation might lead to leaks or system failures.

In essence, while the benefits are clear, challenges exist. Users may struggle with selecting compatible valves. Maintenance also becomes essential for longevity. A Motorized Valve can save time and energy but requires attention. Exploring these aspects reveals the intricate balance between efficiency and complexity.

What is a Motorized Valve?

A motorized valve is a device that automatically controls fluid flow. It typically consists of a valve body and an actuator. The actuator can be electric, pneumatic, or hydraulic. This combination allows the valve to open or close based on specific signals. Motorized valves are widely used in heating, cooling, and water systems.

When a signal is sent to the actuator, it moves the valve. This movement can either open or close the flow path. Many people rely on this automation to improve efficiency. However, issues can arise. Sometimes the actuator fails, causing improper flow control. Regular maintenance is essential to avoid this.

Motorized valves come in various sizes and materials. They can fit into different systems, whether residential or industrial. Understanding how these valves work is crucial for effective management. Awareness of their limitations is just as important. Mistakes in installation or use can lead to significant problems. Each application requires careful consideration of valve performance.

Components of a Motorized Valve

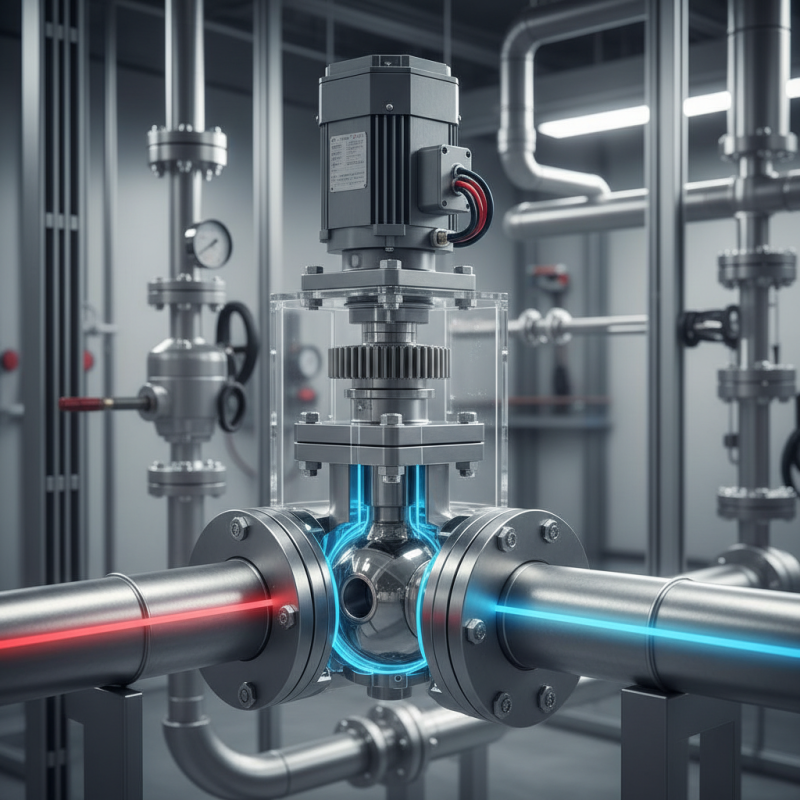

Motorized valves play a crucial role in various industries by controlling fluid flow. These valves are composed of several key components. The actuator is the heart of the motorized valve. It converts electrical energy into mechanical motion. This motion opens or closes the valve, ensuring precise control.

Another important component is the valve body. It houses the internal mechanisms. The valve body can be made from different materials, such as brass or stainless steel. Each material has its own advantages and disadvantages. Seals and gaskets are also vital. They prevent leaks and ensure durability. However, they may wear out over time.

Sensors are often incorporated into motorized valves. They provide feedback on the valve's position. This feature can help in automation. In some cases, the connection between the actuator and valve body may not align perfectly. This can lead to issues in operation. Regular maintenance is essential to avoid such problems. Operators should review these components regularly to ensure optimal performance.

Motorized Valve Performance Metrics

How Motorized Valves Operate

Motorized valves play a crucial role in various systems. They are devices that control fluid flow automatically. These valves often use electric motors to operate. When the motor receives a signal, it moves the valve open or closed. This process can be incredibly efficient for managing liquids or gases.

How do these valves work? They typically have a shaft connected to the valve body. As the motor rotates the shaft, it changes the valve position. This simple mechanism enables precise flow management. However, sometimes there can be issues with responsiveness. Delays in the signal might affect performance. Moreover, ensuring a proper power supply is essential for reliable operation.

The design of motorized valves can vary. They may include feedback systems that report the valve's position. This feature helps in monitoring operations better. Yet, it might also complicate maintenance. Users must be careful when troubleshooting these valves. Overall, understanding their function is vital for effective applications in HVAC systems, industrial processes, and irrigation setups.

Applications of Motorized Valves

Motorized valves play a crucial role in various industries. They are used to control the flow of fluids in systems like heating, ventilation, and air conditioning (HVAC). These valves can automatically open or close based on external signals, which enhances efficiency. In industrial processes, motorized valves regulate flow rates to ensure optimal performance.

In water treatment facilities, motorized valves help in managing chemical dosing. They allow precise control, preventing over- or under-dosing of chemicals. This precise control is vital for maintaining water quality. In the oil and gas sector, these valves contribute to safety as they can quickly shut off the flow in emergencies.

Tips: Regularly inspect motorized valves for signs of wear. Small issues can lead to larger problems down the line. Additionally, ensure the power supply is consistent to avoid valve malfunction. Utilizing a manual override option can also be helpful during power outages.

These valves are essential for automation. However, they require proper maintenance. Ignoring routine checks can lead to failures. It's important to train staff on troubleshooting to minimize downtime. Understanding how each valve operates within a system is crucial for optimal function.

Benefits and Limitations of Motorized Valves

Motorized valves offer several benefits that streamline various industrial applications. They automate the opening and closing of valves, enhancing efficiency and reducing the need for manual operation. This automation minimizes human error and optimizes system control. As a result, businesses can maintain desired flow rates with precision.

In scenarios where quick response times are critical, motorized valves shine. They react swiftly to changes in system requirements, improving operational uptime.

However, motorized valves come with limitations. Maintenance can be more complex than traditional valves. If a motor fails, it may disrupt the entire system. Additionally, these valves can be more expensive upfront, which may deter smaller operations from investing in them. Dependable electricity sources are essential for these valves to function correctly. If power interruptions occur, it can lead to significant setbacks.

Despite their advantages, it's essential to assess your specific needs. Not every application requires the advanced capabilities of motorized valves. Sometimes, a simpler solution may suffice. Evaluating your system's requirements carefully can lead to better decision-making. Remember, the best choice aligns with your operational goals and resources.