How to Optimize Injection Molding Machines With Robots?

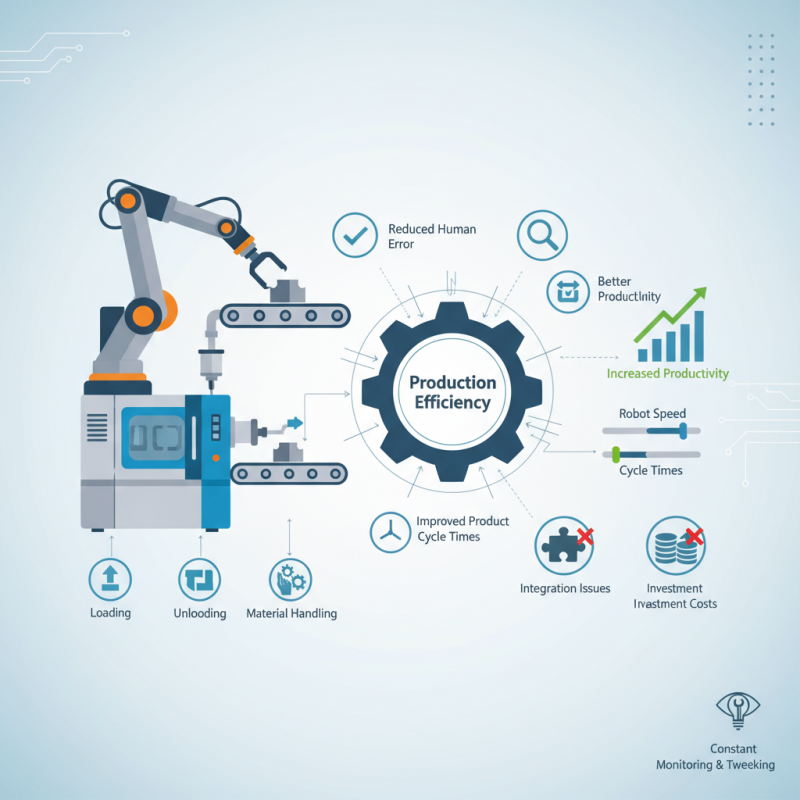

Optimizing an Injection Molding Machine With Robot technology can significantly enhance production efficiency. This process integrates robotics to handle tasks like loading, unloading, and material handling. Automation reduces human error, leading to better product quality.

Implementing robots in injection molding is not without challenges. Integration issues may arise, requiring careful planning and adaptation. Additionally, investment costs for robotics can be steep. Understanding the specific needs of each operation is crucial for success.

By focusing on the right parameters, companies can improve their workflow. For example, adjusting robot speed and cycle times can yield better results. Emphasizing these aspects can lead to fewer disruptions and increased productivity in molding operations. However, constant monitoring and tweaking are necessary for optimal performance.

Understanding Injection Molding Machines and Their Components

Injection molding is a crucial process in manufacturing. It involves injecting molten plastic into a mold to create specific shapes and components. Understanding the machine's components is vital for optimizing performance. Key parts include the hopper, screw, barrel, and mold. Each plays a role in ensuring efficiency and precision. According to recent industry reports, improper settings can lead to around 20% production loss.

The hopper feeds raw material into the system. Material must be dry and properly sized. Moreover, the screw rotates to mix and push the material forward. A report by the Society of Plastics Engineers highlights that screw design impacts melting efficiency significantly. If the temperature isn’t controlled, the material can degrade, leading to waste. The mold creates the final product's shape, making its design critical. Variations in mold temperature can cause defects.

Regular maintenance of injection molding machines is also essential. Inconsistent performance can lead to increased cycle times and higher scrap rates. Some operators overlook minor wear and tear, resulting in larger issues. Monitoring for signs of wear can help prevent these challenges. Implementing robots can streamline this process. Robots automate loading, unloading, and quality inspection. This integration can improve accuracy and reduce manual errors. Nevertheless, reliance on robotic systems must be balanced with human oversight to ensure optimal performance.

How to Optimize Injection Molding Machines With Robots?

| Component | Function | Optimization Strategies | Impact on Efficiency |

|---|---|---|---|

| Injection Unit | Melts plastic pellets for injection | Use heat sensors for optimal temperature control | Improves melt consistency and reduces waste |

| Clamping Unit | Holds the mold in place during injection | Integrate robotic mold handling systems | Increases cycle time efficiency |

| Cooling System | Removes heat from the mold | Optimize cooling channel layout | Reduces cooling time and increases output |

| Robot Arm | Automates part removal and placement | Use AI for motion planning | Improves precision and reduces cycle time |

| Control System | Manages the machine operations | Implement predictive maintenance algorithms | Minimizes downtime and enhances reliability |

The Role of Robotics in Injection Molding Optimization

Robotics plays a crucial role in optimizing injection molding processes. Robots can handle a range of tasks with precision. They assist in material loading and part removal, which improves efficiency. When integrated properly, robots enhance cycle times. This leads to faster production rates and reduced costs. However, ensuring seamless collaboration between machines and robots is challenging.

Some companies may face technical hurdles during implementation. For instance, improper programming can lead to errors in part handling. This affects output quality, resulting in increased waste. Moreover, operators sometimes struggle to adapt to new technologies. Training is essential but often overlooked. The integration phase can be a period of trial and error.

Despite these difficulties, the benefits of robotics are significant. Automated systems can operate in environments unsuitable for humans. They ensure consistent quality and reduce manual labor. As the industry progresses, continuous evaluation of robotic systems will be necessary. This can help address issues and improve overall performance. Companies must remain adaptable to harness the full potential of automation in injection molding.

Injection Molding Optimization Factors

This chart illustrates the various factors impacted by robotics in the optimization of injection molding machines. Each factor shows the percentage improvement observed when robots are integrated into the process.

Evaluating the Benefits of Automation in Molding Processes

Automation in molding processes offers substantial benefits, transforming efficiency and precision. According to a report by the Association for Manufacturing Technology, companies that implemented automation saw production efficiency increase by 20%. Robots reduce cycle times effectively, allowing for faster project completions.

Despite these advantages, not every mold shop is ready for automation. The initial investment can be daunting. While robots can perform repetitive tasks with precision, they require proper programming and maintenance. A study from Expert Market Research indicates that over 30% of manufacturers hesitate due to these costs.

Moreover, training staff to interact with robotic systems is essential. Employees may feel uncertain about their roles. Balancing human skill with machine efficiency is necessary. As businesses automate, ensuring workforce adaptability remains a critical concern, requiring ongoing evaluation.

Integrating Robots with Injection Molding Machines: Key Considerations

Integrating robots with injection molding machines can greatly enhance efficiency. However, there are several key considerations to keep in mind. First, the layout of the production floor should be optimized.

Robots need enough space to operate without disrupting other machinery. It's important to map out a detailed plan before implementation.

Another aspect is the communication between robots and molding machines. For seamless operation, standardization of protocols is crucial. If the machines cannot effectively communicate, delays can occur, leading to inefficiencies. Testing these systems thoroughly helps identify issues before full integration.

Training staff is also essential. Employees need to understand how to operate the new robotic systems. This can take time, and initial resistance may occur.

Improving employee confidence is vital. Engage them in the process to ensure a smoother transition. It is a common issue that workers might feel threatened by automation. Address these concerns with open discussions.

Best Practices for Maintenance and Upkeep of Robotic Systems in Molding

Maintaining robotic systems in injection molding is essential for efficiency. Regular maintenance schedules can prevent unexpected breakdowns. According to a report by the Robotics Industry Association, well-maintained systems can boost production efficiency by up to 30%. This statistic shows the direct link between upkeep and productivity.

Daily checks are vital. Inspecting joints and cables ensures all is well. These small actions can avoid larger issues down the line. For instance, worn components can lead to operational delays. A recent study indicated that unplanned downtime caused by neglect can cost manufacturers about $25,000 per hour.

Furthermore, training staff on best practices is crucial. Operators must identify potential problems early. Simple training can help reduce maintenance costs by 20%. However, many facilities overlook this aspect. Investing in skill development can yield significant long-term savings.