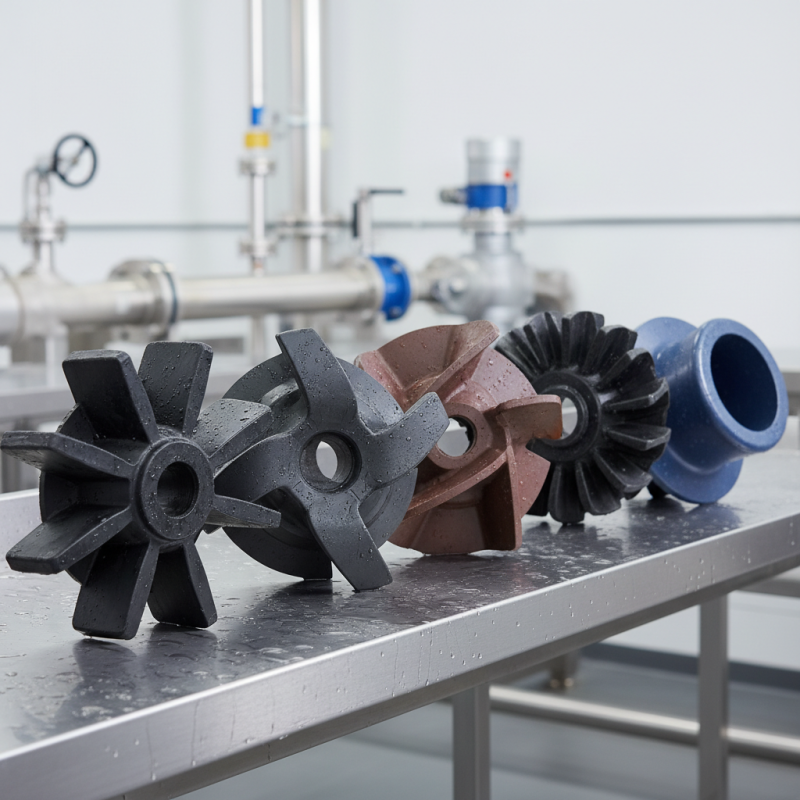

Top 5 Rubber Pump Impeller Types and Their Benefits?

Rubber Pump Impeller designs play a crucial role in various industrial applications. Choosing the right type can significantly enhance performance and efficiency. The diverse options available can make the selection process overwhelming. Each type has its strengths and weaknesses, which add to the complexity.

Understanding the benefits of different Rubber Pump Impeller types is essential for optimal performance. For example, some impellers excel in handling abrasive materials. Others, however, may not perform well under certain conditions. Selecting the wrong type could lead to increased wear and maintenance costs. This is an important aspect that deserves careful consideration.

In this guide, we will explore the top five Rubber Pump Impeller types and their unique advantages. By diving into their specific features, you can make a more informed choice. This exploration aims to clarify the confusion surrounding rubber impellers. Ultimately, knowledge is key for successful and efficient pump operation.

Understanding Rubber Pump Impellers: An Overview

Rubber pump impellers play a crucial role in fluid transfer systems. They are designed to enhance performance and efficiency. Understanding their types can significantly impact operations. These impellers are typically made from elastic materials, allowing them to withstand wear and tear over time. Different shapes and designs cater to various pumping needs.

There are several types of rubber pump impellers. Open impellers facilitate easy flow and reduce clogging. They are ideal for handling solid-laden liquids. On the other hand, closed impellers provide higher efficiency for clean liquids. Their enclosed design helps to minimize turbulence and energy loss. Each type offers specific benefits that need evaluation based on application.

The choice of impeller is not always straightforward. One must consider factors like fluid type and temperature. Improper selection can lead to performance issues. It can also increase operational costs. Understanding the unique characteristics of each rubber pump impeller type is essential for optimizing performance.

Types of Rubber Pump Impellers and Their Unique Features

Rubber pump impellers come in various types, each designed for specific applications. This diversity enhances performance and efficiency in different environments. For instance, open impellers can handle larger solids. Their design minimizes clogs, making them ideal for sewage treatment. According to the latest industry report, open impellers improve flow rates by up to 30% in wastewater applications.

Closed impellers feature blades that create a tighter seal. They are efficient in transferring energy, making them suitable for high-pressure systems. This design reduces turbulence, increasing the overall pump efficiency. A study highlighted that closed impellers can boost the overall system performance by 25%. However, they may struggle with highly viscous fluids, requiring careful consideration in selection.

Vortex impellers, on the other hand, handle solids without clogging. They create a vortex to move the liquid, which is beneficial for slurries. Although effective, these impellers may have lower efficiency in clear liquids. A common misconception is that their design guarantees high performance in all scenarios. It’s essential to assess the specific application needs before choosing the right type. Understanding each impeller’s unique features helps optimize pumping systems for various industrial applications.

Top 5 Rubber Pump Impeller Types and Their Benefits

This chart illustrates the benefits of the top 5 rubber pump impeller types based on key performance indicators, including efficiency, durability, cost-effectiveness, resistance to wear, and ease of maintenance.

Benefits of Using Rubber Impellers in Fluid Transfer Applications

Rubber impellers are widely used in fluid transfer applications due to their unique advantages. These impellers excel in environments where corrosive substances are present. They resist wear and tear, ensuring durability over time. Additionally, rubber impellers provide excellent flexibility, allowing for better flow management. This feature is particularly beneficial in various industrial processes.

One of the standout benefits of rubber impellers is their ability to absorb vibrations. This quality helps in reducing noise levels during operation. Lower noise can lead to a more pleasant work environment. Moreover, rubber has good sealing properties, minimizing the risk of leaks. However, some may find rubber impellers less efficient in high-temperature applications. This limitation should be considered when selecting an impeller type.

Maintenance is another area where rubber impellers shine. They often require less frequent maintenance compared to metal counterparts. This aspect can lead to cost savings over time. However, one must regularly check for signs of degradation. Regular monitoring ensures optimal performance remains consistent. With these considerations, rubber impellers can be a valuable choice in fluid transfer systems.

Comparative Analysis: Rubber vs. Other Impeller Materials

Rubber pump impellers stand out due to their unique properties. They offer excellent flexibility and resistance to wear. When comparing rubber with other materials, notable differences arise. For instance, rubber impellers often provide better shock absorption. This unyielding elasticity can help prevent damage during operation.

In contrast, metal or plastic impellers may fracture under extreme conditions. They can also be susceptible to corrosion, reducing overall lifespan. Rubber can withstand harsh environments, such as chemicals and varying temperatures. However, it may not be suitable for high-pressure applications.

Sometimes, rubber impellers can lose rigidity over time. This degradation can affect performance, necessitating routine inspections. Understanding the advantages and drawbacks of rubber compared to alternatives is essential for making informed decisions. It’s clear that selecting the right material is a nuanced process, warranting deep consideration of the specific application at hand.

Selecting the Right Rubber Impeller for Your Pumping Needs

Selecting the right rubber impeller for your pumping needs is crucial. The impeller type affects efficiency and overall performance. Data indicates that a well-selected impeller can improve flow rates by up to 25%. However, choosing an inappropriate one may lead to reduced efficiency.

Consider your application's specifics. Different operations demand different qualities. For example, chemical resistance is vital for certain fluids. An impeller with poor resistance can degrade quickly, costing money and time. Industry studies show that about 15% of pumps fail due to improper impeller selection.

It's essential to weigh the benefits of each type. A radial impeller suits high-flow applications, while a mixed flow impeller provides a balance between speed and head. Each choice has implications. Misalignment with your pumping needs may require further adjustments. This often leads to unexpected downtime. Ultimately, understanding your requirements helps you avoid pitfalls.