Ultimate Guide to Die Casting Molds What You Need to Know?

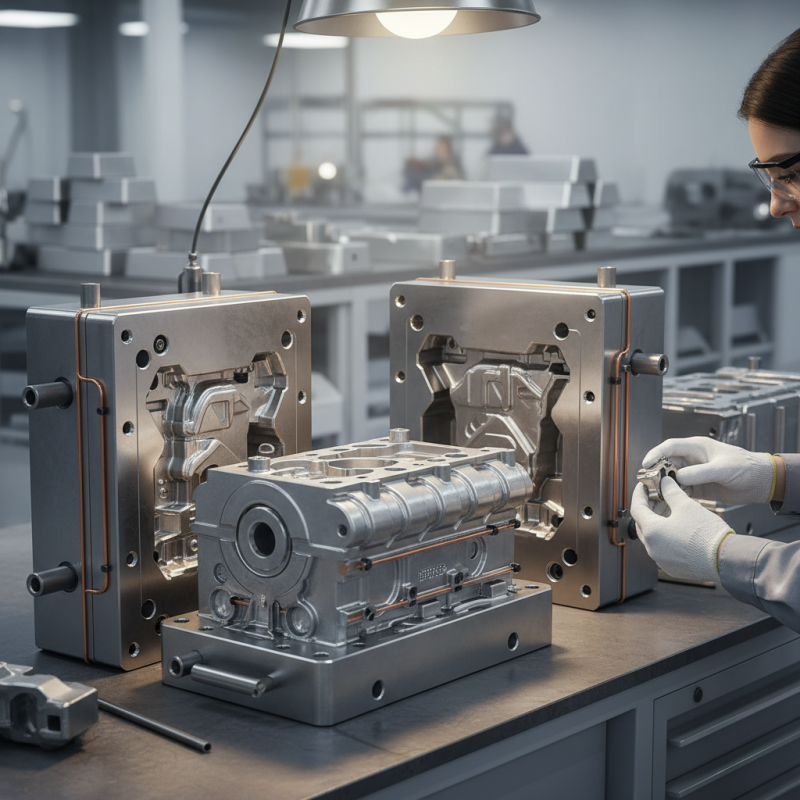

In the world of manufacturing, "Die Casting Molds" play a crucial role. Renowned expert Dr. Jane Thompson once said, "The quality of the mold directly impacts the final product's integrity." This statement underscores the importance of understanding die casting molds for anyone in the industry.

Die casting molds are essential tools for producing metal parts with precision. They allow manufacturers to create complex shapes and designs efficiently. However, many overlook the intricacies involved in mold design and maintenance. Choosing the right material, cooling systems, and even venting can greatly affect the outcome.

Errors in mold production can lead to defects, wasting resources and time. It's a critical area that demands attention. While die casting molds can enhance production efficiency, they require constant evaluation. Reflecting on the mold's performance can reveal areas for improvement. Understanding the intricacies of die casting molds is not just beneficial—it's necessary.

Understanding Die Casting: An Overview of the Process

Die casting is a manufacturing process that creates metal parts. Molten metal is injected into molds. These molds shape the final product. The process is quick and efficient, making it popular in various industries.

However, not everything goes smoothly. Designing molds can be complex. The mold needs precision to avoid defects. If the mold is not made accurately, flaws occur. These can include surface imperfections or structural weaknesses. Proper planning and testing of molds are crucial to achieving quality parts.

Temperature control also plays a key role. If the metal cools too quickly, it can lead to cracks. On the other hand, slow cooling may create uneven textures. Striking a balance is essential. Manufacturers often struggle with these factors. Continuous improvement in the die casting process is necessary to address these challenges.

Ultimate Guide to Die Casting Molds: What You Need to Know

| Mold Type | Material | Temperature Range (°C) | Durability (Cycles) | Cost ($) |

|---|---|---|---|---|

| Aluminum Molds | Aluminum | 200-600 | 50,000 | 5,000 |

| Steel Molds | Steel | 200-800 | 500,000 | 20,000 |

| Copper Molds | Copper | 200-600 | 100,000 | 15,000 |

| Sodium Molds | Sodium | 200-700 | 80,000 | 10,000 |

Types of Die Casting Molds: Characteristics and Applications

Die casting molds come in various types, each with unique characteristics and applications. One common type is the multi-cavity mold. This design allows for high production rates. It can produce several identical parts in one cycle. However, it requires precise engineering and setup. If not managed well, it can lead to defects and wasted material.

Another type is the slip casting mold. This mold type is excellent for intricate designs. It suits complex shapes where a smooth finish is necessary. Yet, it has its downsides. The drying time can be prolonged, which affects lead times. Manufacturers must balance detail with efficiency.

Tooling costs can also vary significantly with different molds. A simple mold may be cheaper. However, complex molds can skyrocket expenses. Designers often wrestle with cost versus functionality. They sometimes overlook potential improvements in production processes. Finding the right type means understanding specific project needs. Each mold influences not just production speed but quality and cost.

Materials Used for Die Casting Molds: A Comprehensive Guide

Die casting molds play a crucial role in the manufacturing process. The materials used for these molds greatly affect the quality and durability of the final product. Commonly, aluminum and steel are popular choices. Aluminum is lightweight and has excellent thermal conductivity. It heats and cools quickly, making it suitable for complex designs. However, it may not last as long as steel in high-volume production.

Steel, on the other hand, is robust and can withstand high pressure and temperature. It’s ideal for producing large quantities of components. Despite its advantages, steel molds require more time and cost to produce. Some manufacturers experiment with other materials, like copper or even ceramic. These alternatives can offer unique benefits, but they often come with challenges in terms of temperature management and production speed.

Choosing the right material involves balancing durability, cost, and production efficiency. Some unexpected factors may arise, such as wear and tear on molds during production. Knowing when to replace these molds is crucial, yet many tend to overlook this. It's essential to continually assess mold performance to achieve optimal results. This reflection can lead to better decisions in future projects and improvements in overall production quality.

Maintenance and Care for Die Casting Molds: Best Practices

Proper maintenance and care for die casting molds is crucial for their longevity. Regular cleaning helps remove metal residues that can build up over time. A dedicated cleaning solution should be used. This ensures the mold surfaces remain smooth and free from defects. After cleaning, it’s important to thoroughly dry the molds. Moisture left on them can lead to rust and premature wear.

Inspecting molds regularly is another key practice. This includes checking for any signs of wear or damage. Pay attention to the sealing surfaces and cooling channels. Flaws in these areas can affect production quality. It’s wise to keep a log of any issues you find. This allows for better planning of any required repairs.

Lubrication also plays a vital role. Applying a suitable lubricant can reduce friction and wear. However, too much lubricant can attract dirt and debris. Finding the right balance is essential. After all, maintaining die casting molds is an ongoing process. It's easy to overlook small details. Yet, these small details make a significant difference in mold performance.

Die Casting Mold Maintenance Best Practices

Common Challenges and Solutions in Die Casting Mold Production

Die casting mold production faces several common challenges. Accurate mold design is crucial but often overlooked. Many designers miss the importance of cooling channels. These channels significantly affect cycle time and part quality. Without proper cooling, defects may arise. Warping and surface imperfections can occur easily.

Another challenge lies in material selection. Choosing the wrong alloy can lead to brittleness or poor flow. Understanding the characteristics of various metals is essential. It’s vital to test different materials to find the right fit. Sometimes, even slight variations in composition can yield unexpected results. Experimentation might be necessary.

Quality control in die casting is also a significant hurdle. Maintaining consistency throughout the production process is not always easy. Mold wear and tear can impact final products. Regular maintenance is needed but often neglected. Inspecting molds frequently can help prevent larger issues later on. Neglecting this can result in greater production costs and delays.